Flexographic (flexo) printing plays a crucial role in the food packaging industry. The ability to print on a variety of substrates, from plastics to paper, combined with its speed, cost-effectiveness, and versatility, has made flexo printing the preferred choice for packaging food products. However, the demands of food packaging, especially in terms of safety, hygiene, and compliance with regulations, require careful consideration.

This article will explore the advantages of flexo printing in food packaging and the critical factors that ensure its safety and effectiveness.

Why Flexo Printing is Ideal for Food Packaging

1. Versatility Across Substrates

Flexo printing can print on a wide range of materials commonly used in food packaging, including:

- Plastic films: Polypropylene (PP), polyethylene (PE), and polyethylene terephthalate (PET) used for flexible food packaging.

- Paper: For snack packaging, paper bags, and wraps.

- Foils: Aluminum foil or metallized films used in products that require barrier properties, like chips and chocolate.

- Laminated Substrates: Used for multi-layered packaging, often necessary for preserving food freshness and increasing shelf life.

This adaptability across substrates makes flexo printing an ideal solution for the diverse needs of the food industry.

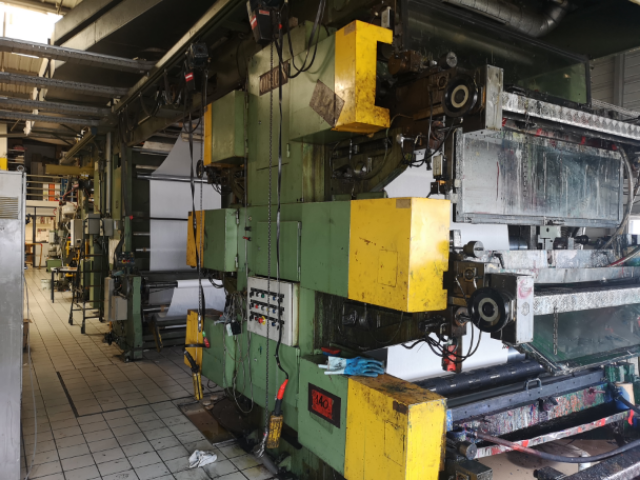

2. High-Speed Production

Flexo printing is a high-speed process capable of printing on large volumes of material efficiently. The high throughput ensures that food packaging can be printed quickly to meet the tight schedules of food manufacturers.

3. Cost-Effectiveness

The use of photopolymer plates in flexo printing allows for longer production runs with less frequent plate changes, making it cost-efficient, especially for large print runs. Additionally, the water-based and UV inks used in flexo printing are relatively inexpensive compared to other types of printing inks, making it a highly economical option for food packaging.

4. Print Quality and Design Flexibility

Flexo printing offers high-quality prints, ensuring sharp images, vibrant colors, and clear text on food packaging. The ability to print detailed graphics and product information is essential for food packaging, as it influences consumer appeal and brand perception. Modern flexo printing presses allow for excellent color registration and the use of spot colors, gradients, and complex designs, which are critical for food brands looking to stand out on store shelves.

5. Eco-Friendly Ink Options

Sustainability is a growing priority for both food manufacturers and consumers. Flexo printing uses water-based, UV-curable, or low-VOC (volatile organic compounds) inks, which are more environmentally friendly than solvent-based inks traditionally used in other printing methods. These inks dry quickly, reducing energy consumption during the printing process. The move toward using biodegradable or recyclable substrates also aligns with flexo printing’s eco-friendly capabilities.

Food-Safe Inks and Compliance with Regulations

One of the most critical considerations when using flexo printing for food packaging is the use of food-safe inks. Since food packaging often comes into direct or indirect contact with consumables, ensuring that the printing process does not contaminate the food is of paramount importance.

1. Food-Safe Inks

Inks used for printing food packaging must comply with regulations that ensure they do not contain harmful substances that can migrate into the food. The inks must be formulated specifically for food-safe applications, and the following types of inks are commonly used in food packaging:

- Low-Migration Inks: These inks are designed to minimize the transfer of ink components from the printed surface into the food product. They are specifically formulated to be safe for indirect food contact.

- Water-Based Inks: These are commonly used in flexo printing for food packaging because they have fewer volatile compounds and are considered safer for applications where food contact might occur.

- UV-Curable Inks: UV inks cure quickly under ultraviolet light, which prevents the risk of ink migration. These inks are popular in food packaging because they produce high-quality prints with minimal risk of contamination.

2. Regulatory Standards

Packaging for food must adhere to strict regulatory standards to ensure safety

Compliance with these regulations ensures that food packaging does not compromise food safety and consumer health.

Hygiene and Safety Considerations

In food packaging, maintaining hygiene throughout the printing process is critical. Manufacturers must follow good manufacturing practices (GMP) to ensure that the packaging does not introduce contaminants into the food supply chain. Some key practices include:

- Cleanroom Environments: Flexo printing facilities for food packaging often have strict cleanliness requirements to minimize contamination risks.

- Controlled Ink Application: Ink transfer methods and the use of anilox rolls in flexo printing ensure precise ink application, reducing the risk of over-inking or ink spillage.

- Low VOC and Low Odor: The use of low-VOC inks not only benefits the environment but also prevents strong odors, which could affect the sensory qualities of packaged food.

Flexo Printing Applications in Food Packaging

Flexo printing is used across a wide range of food packaging applications, including:

- Flexible Packaging: Pouches, wraps, and bags for snacks, frozen foods, and fresh produce. Flexo printing allows for vibrant graphics on flexible films that offer essential barrier properties for food preservation.

- Labels: Adhesive labels on bottles, jars, and plastic containers are commonly printed using flexo technology, ensuring high-quality prints and adhesion to various surfaces.

- Cartons and Boxes: Flexo printing is widely used for folding cartons, food boxes, and corrugated packaging. It provides excellent print quality while allowing packaging to be functional and protective.

- Shrink Sleeves and Wraps: Flexo is often used for shrink sleeves and wraps that conform tightly to bottles or containers, offering 360-degree branding and design.

Conclusion

Flexo printing is an invaluable process in the food packaging industry, offering unparalleled speed, versatility, and high-quality output. Its ability to handle various substrates and its use of food-safe inks make it ideal for the dynamic and regulated world of food packaging. As the demand for sustainable packaging continues to grow, flexo printing’s compatibility with eco-friendly materials and inks positions it as a critical technology for the future of food packaging.