CERUTTI 28R/B - 9 color rotogravure printing press

Angesagt

CERUTTI 28R/B - 9 color rotogravure printing press

Standort:Europa

oder

anrufen +39 346 4948054

Beschreibung

Availabke for sale a Cerutti 28R 9-color rotogravure printing press.

The machine is available for inspection and demonstration in full working condition, upon prior agreement

Spezifikationen

| Hersteller | CERUTTI |

| Modell | 28R/B |

| Zustand | Gebraucht |

| N° of printing decks | 9 |

| Max web width | 1200 mm |

| Min web width | 600 mm |

| Print cylinder repeat min/max | 480 – 1.000 mm |

| Exceptionally minimum print repeat | 450 mm |

| Max web speed | 250 m/min |

| Materials to be printed | Medium density polyethylene: min. 30 μ | Polyester: 12 - 30 μ | Polypropylene: 18 - 30 μ | Paper/aluminum laminate: max 180 g/m² | Paper: max 180 g/m² | Plain aluminum: min 9 μ - max width 800 mm |

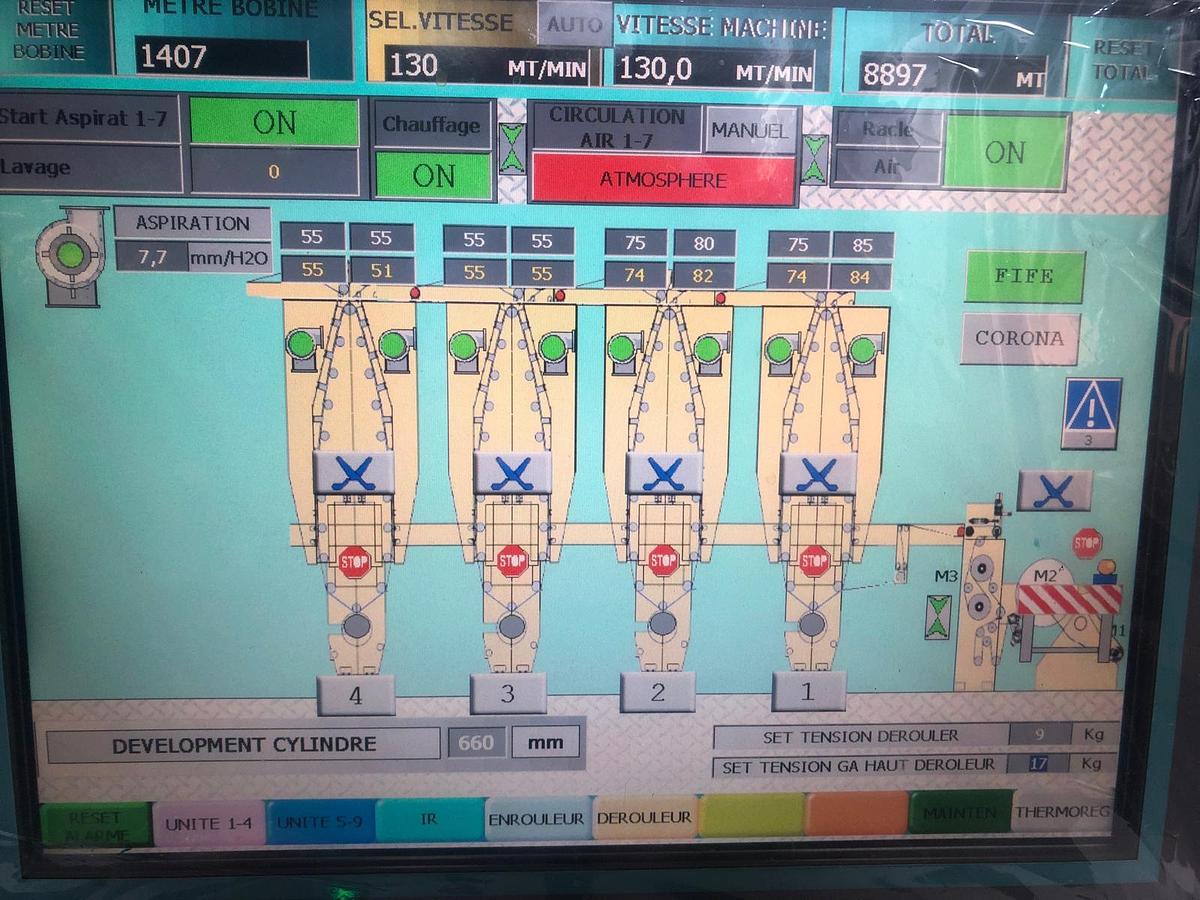

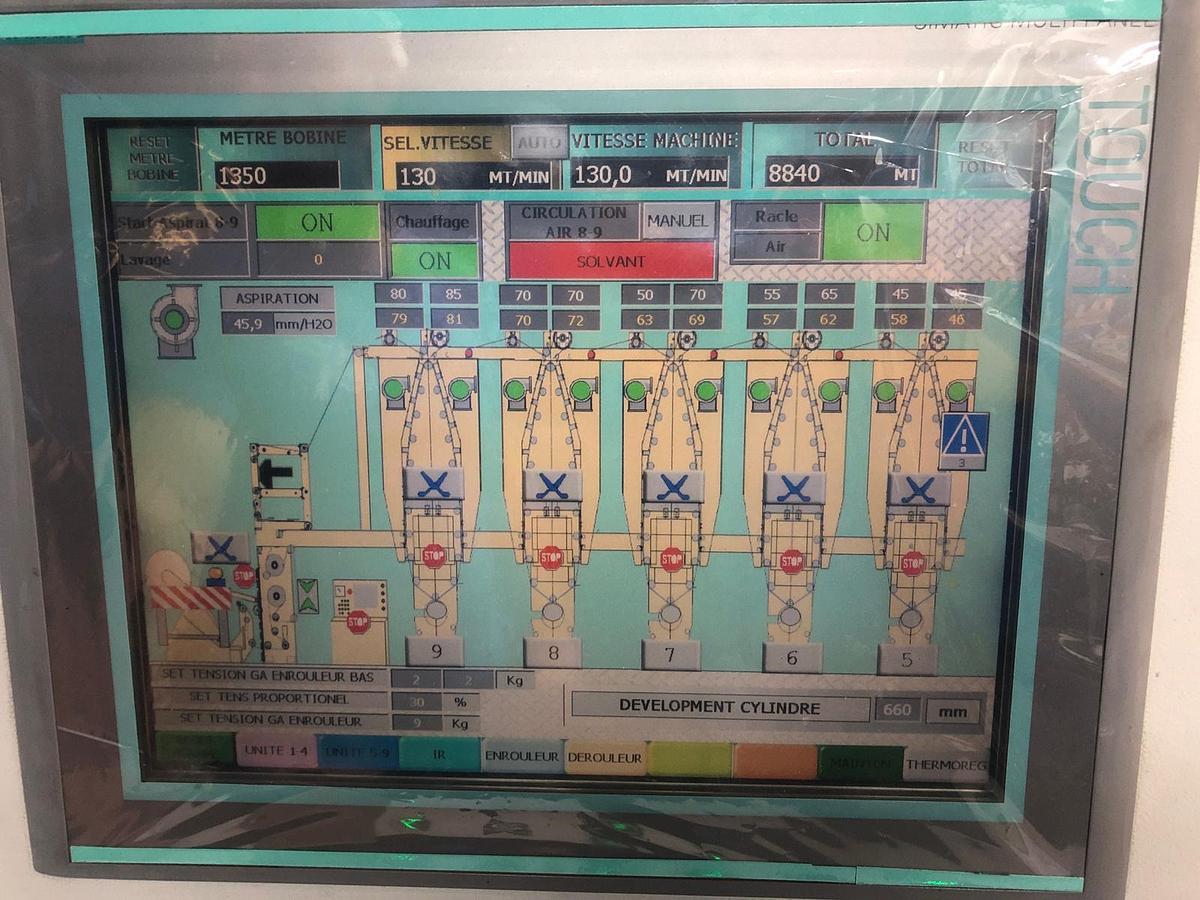

| Rotogravure press configuration | N° 1 UNWINDER MOD. PB32: Web tension min/max: 4 – 50 Kg | Max diameter: 800 mm | Max speed of splice: 250 m/min | Pneumatic expanding shafts for Øint.152 mm / 6 inches cores: N°4 N° 1 DRIVE UNIT NEAR THE UNWINDER: Web tension min/max: 4 – 50 Kg N° 9 PRINTING UNITS: ES 28/B numbered 1 to 6 from right: N°6 | Extended ES 28/B numbered 7 and 8: N°2 | Extended ES 128 L2 numbered 9 for cold seal: N°1 | Reversible ES in positions 1 and 7: N°2 | ES with by window in position 9: N°1 | Sleeve type print cylinder: CERUTTI | Table (our drawing ES24098): 1,270 mm | Pneumatic pressure cylinders: Ø 125 mm | Cooled rollers for ES units: N°2 standard | Air speed variation on 2 chambers, installed on all ES units: Damper regulation | Automatic temperature control via OP SIEMENS HMI | Longitudinal register with compensator, long ball screws with graduated scale | Ink-contact parts: sheet metal – galvanized steel | Doctor blade air supply via fan and relevant manifold | Nozzle-type injectors | Electropneumatic web breakage device on all ES units | N°1 DRIVE UNIT NEAR THE REWINDER: Web tension min/max: 4 – 50 Kg | N°1 REWINDER MOD. RB 28 | Web tension min/max: 4 – 50 Kg | Max diameter: 800 mm | Max speed of splice: 250 m/min | Cardboard cores: Øint. 6”| Pneumatic expanding shafts: N°2 |

| Recirculated air ventilation | Recirculated air ventilation ES 1 – 6 ES 7 – 8 ES 9 | Air Flow Rate (m³/h) (ES 1-6: 6.000 m³/h) (ES 7-8 : 9.000 m³/h) (ES 9: 12.000 m³/h) | Exhaust Flow (m³/h) (ES 1-6: 5.400 m³/h) (ES 7-8: 7.500 m³/h) (ES 9: 10.500 m³/h) | Max Air Temp (°C) (ES 1-6: 120 °C) (ES 7-8: 120 °C) (ES 9: 140 °C) |Air velocity at nozzles (m/s) (ES 1: ≈ 30) (ES 7-8 : ≈ 35) (ES 9: ≈ 40) |

| Accessories | Doctor blade holders: N°18 | Ink pans with side guards: N°18 | Nozzle-type injectors: N°18 | Ink tanks with CEMP AG250 electric pump, 30-liter capacity: N°18 |

| Year | 1982 + 1986 + 1996 |

| Additional information | n°1 corona treatment station softal mod. 6060 | n°1 grafikontrol register system type cr33 (longitudinal and transverse) - s/n 049 – year 2016 | n°9 gama viscosimeters type vis-g25 – year 2012 | n°1 film inspection system grafikontrol matrix– s/n 049 – year 2016 | n°1 web guiding system fife type opg | complete electrical/electronical retrofit - year 2012 |